Industrial Hemp - Educational Seminar

Presented by iHemp member, Eric Anderson, MSU Extension Field Crops Educator, St. Joseph County

An Overview

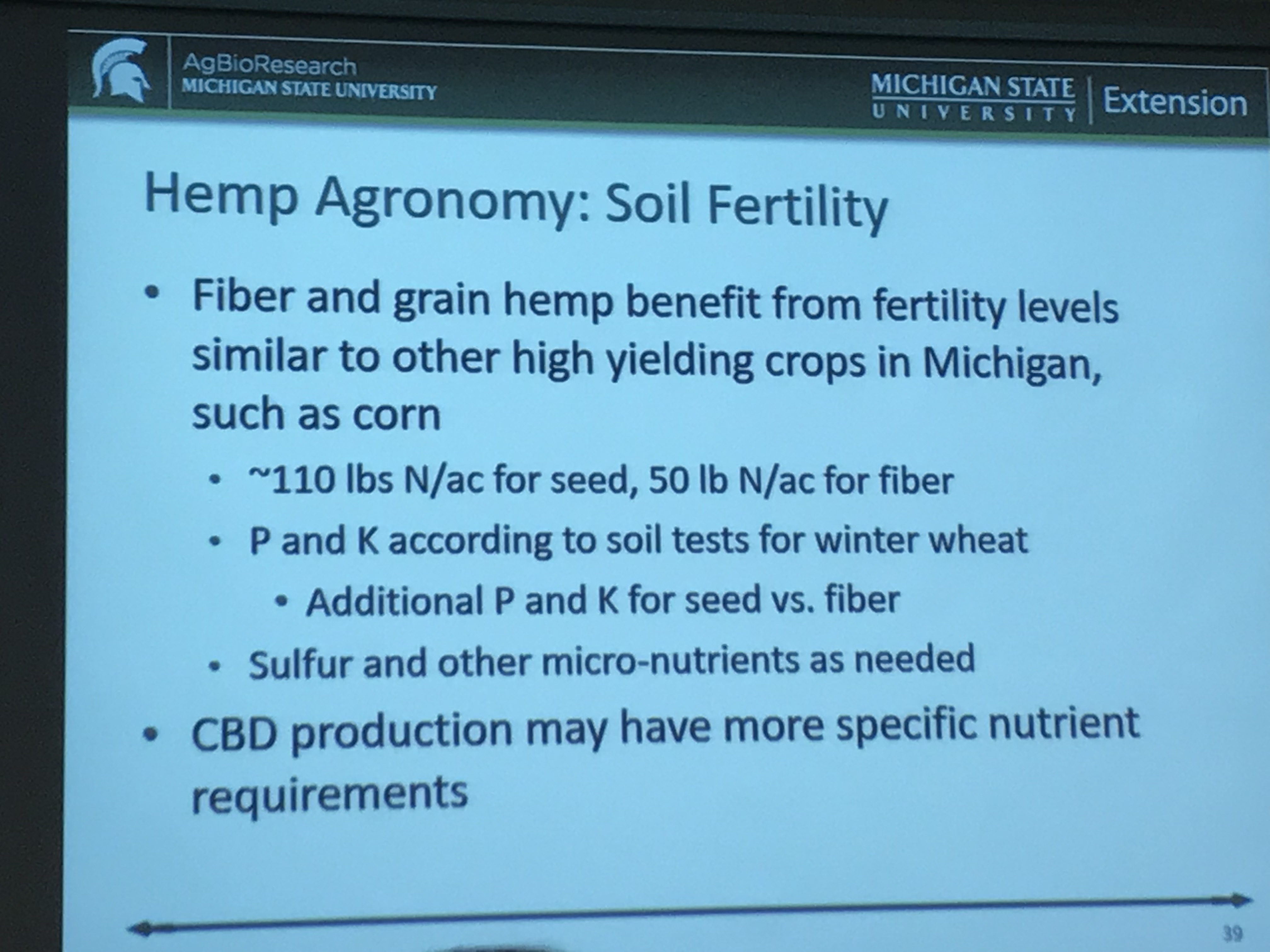

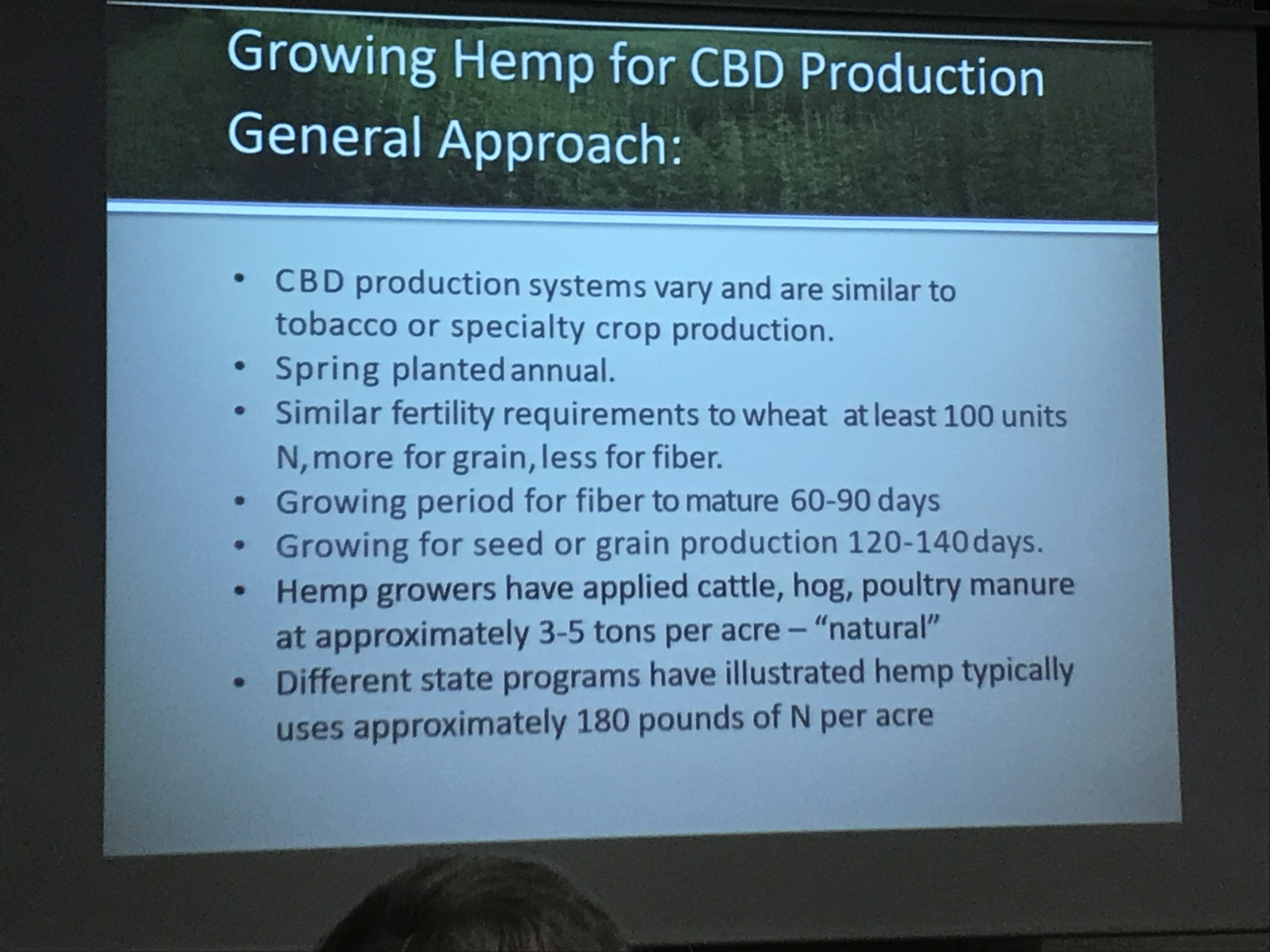

bbAbout sixty people interested in hemp attended the educational seminar in Benton Harbor. Many in the room are iHemp members. Eric reviewed the history and uses along with some interesting economic data that I will share. Chris Veley from Material Control Solutions, LLC explained his chipping equipment and the benefits of chipping prior to processing to maximize CBD extraction. Milon Kluko of Harvest Moon Sustainable Ventures walked us from seed to processing. Milon went deep into his process of germination and cloning using vertical farming techniques and then walked us through CO2 and Ethanol extraction methods.

The more I learn, the less I know! This was a great opportunity to gather, network and learn. We will keep you up to date as always. Look for an invite to a field trip in the future!

To the future!

Dave Crabill

Eric Anderson,

MSU Extension Field Crops Educator

eander32@msu.edu

Telephone: 269-467-5511

Fax: 269-467-5641

Chris Veley,

Material Control Solutions, LLC

Office: 414-423-4472

Fax: 414-423-4473

Email: sales@matconsol.com

http://matconsol.com

Milan Kluko

Harvest Moon Sustainable Ventures

18300 US-12 New Buffalo, MI 49117

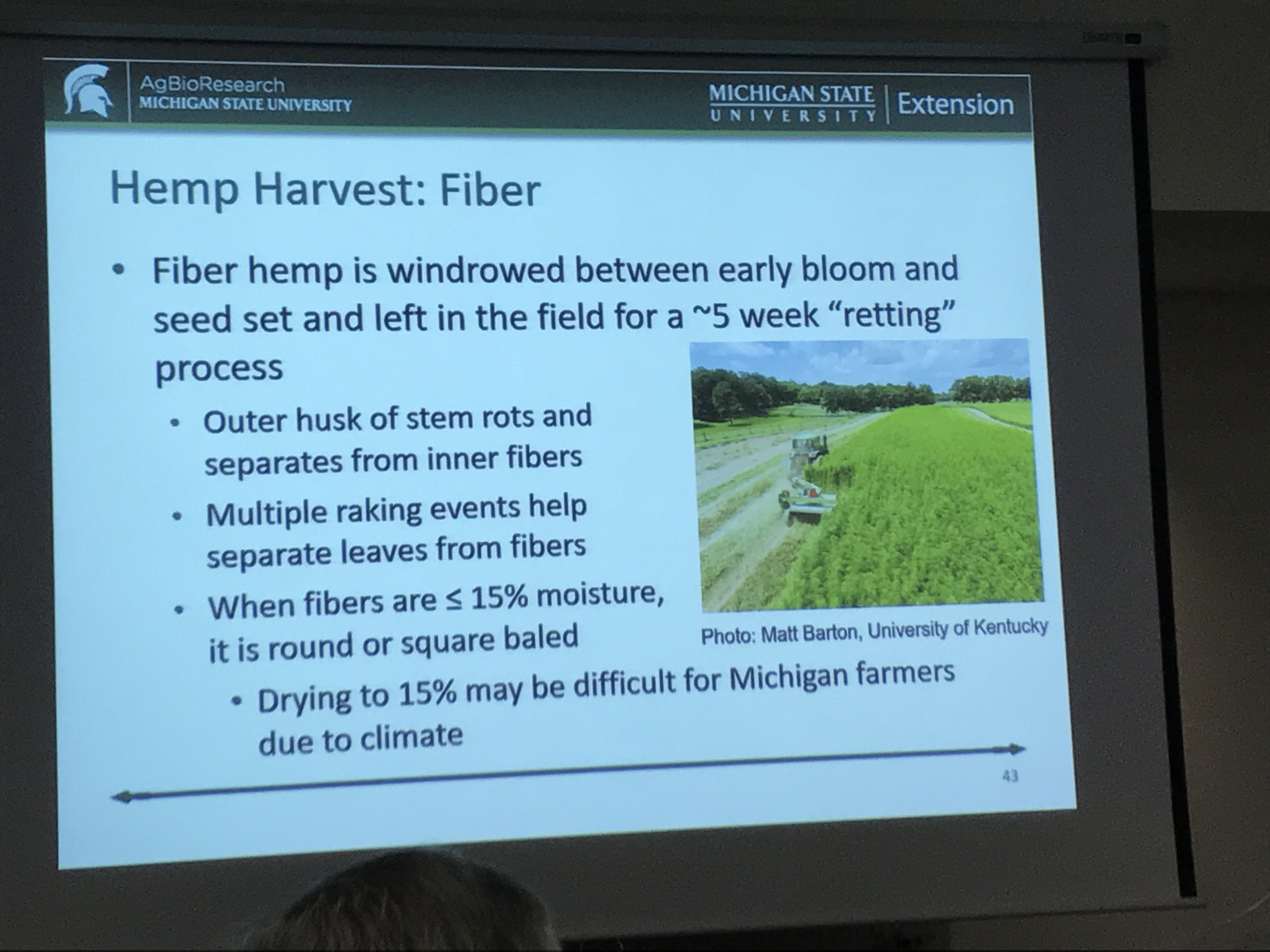

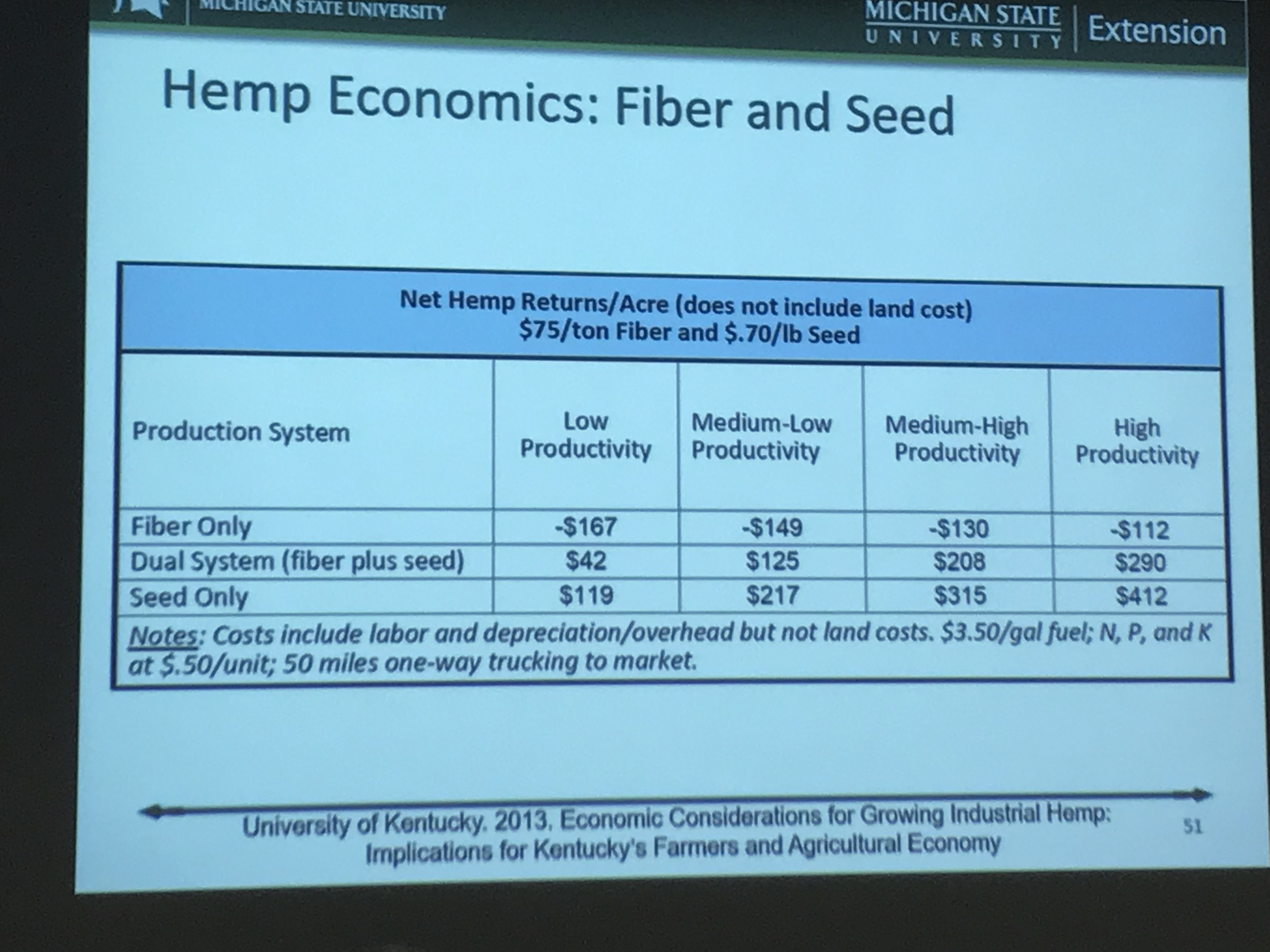

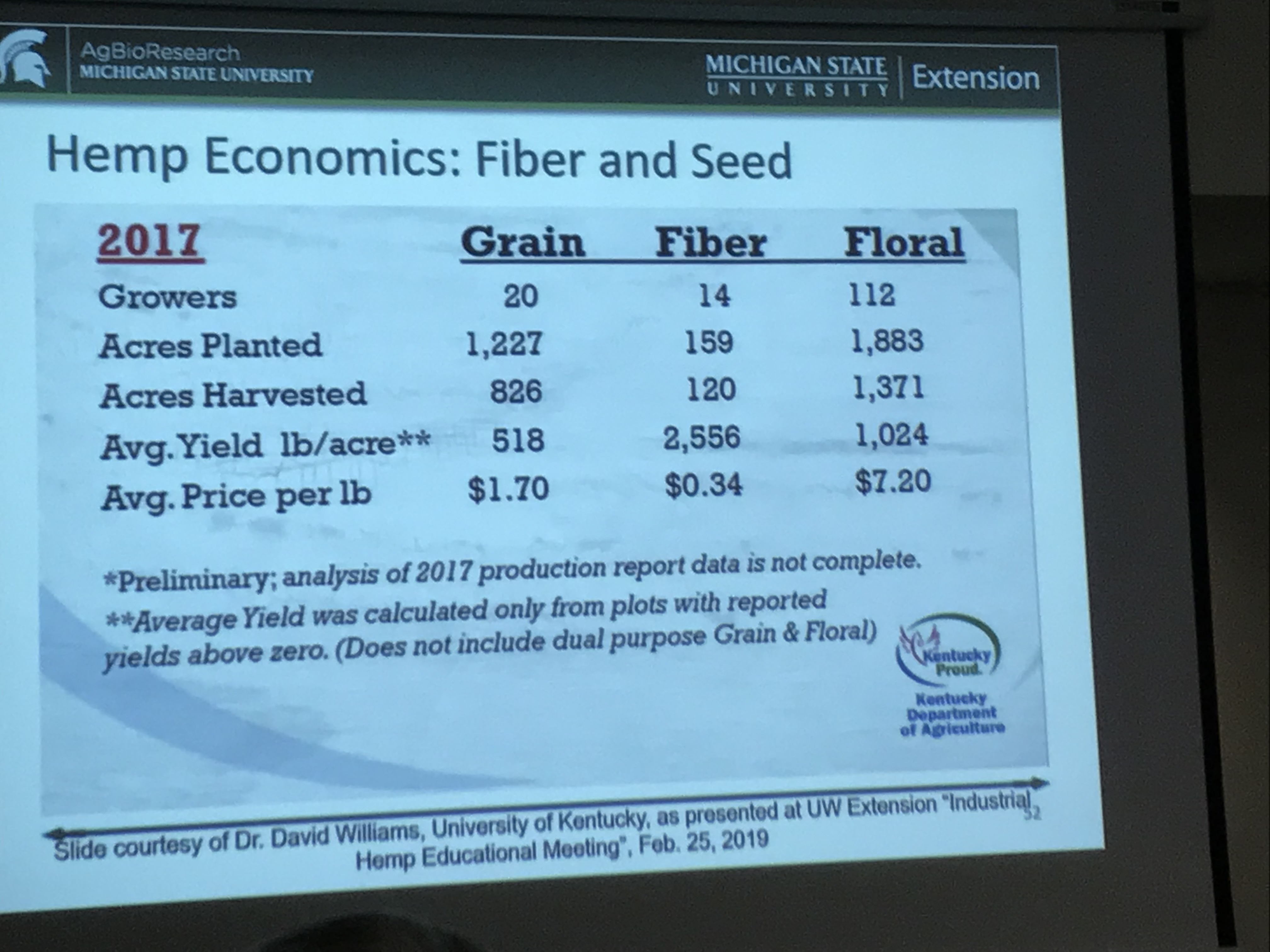

We know of a few grain projects for this season. A processing plant may be developed in Coldwater, MI to process the grain and fiber. Ultimately, we would like to see a future for fiber to replace oil-based plastics. This is a long-range goal and much needs completed to create an infrastructure and technology for this to happen.

Real numbers for the value of grain and fiber are going to vary. As Eric mentioned, this is the wild west as the industrial hemp industry develops. Here is a brief video towards the end of his presentation talking about pricing.

Size Matters

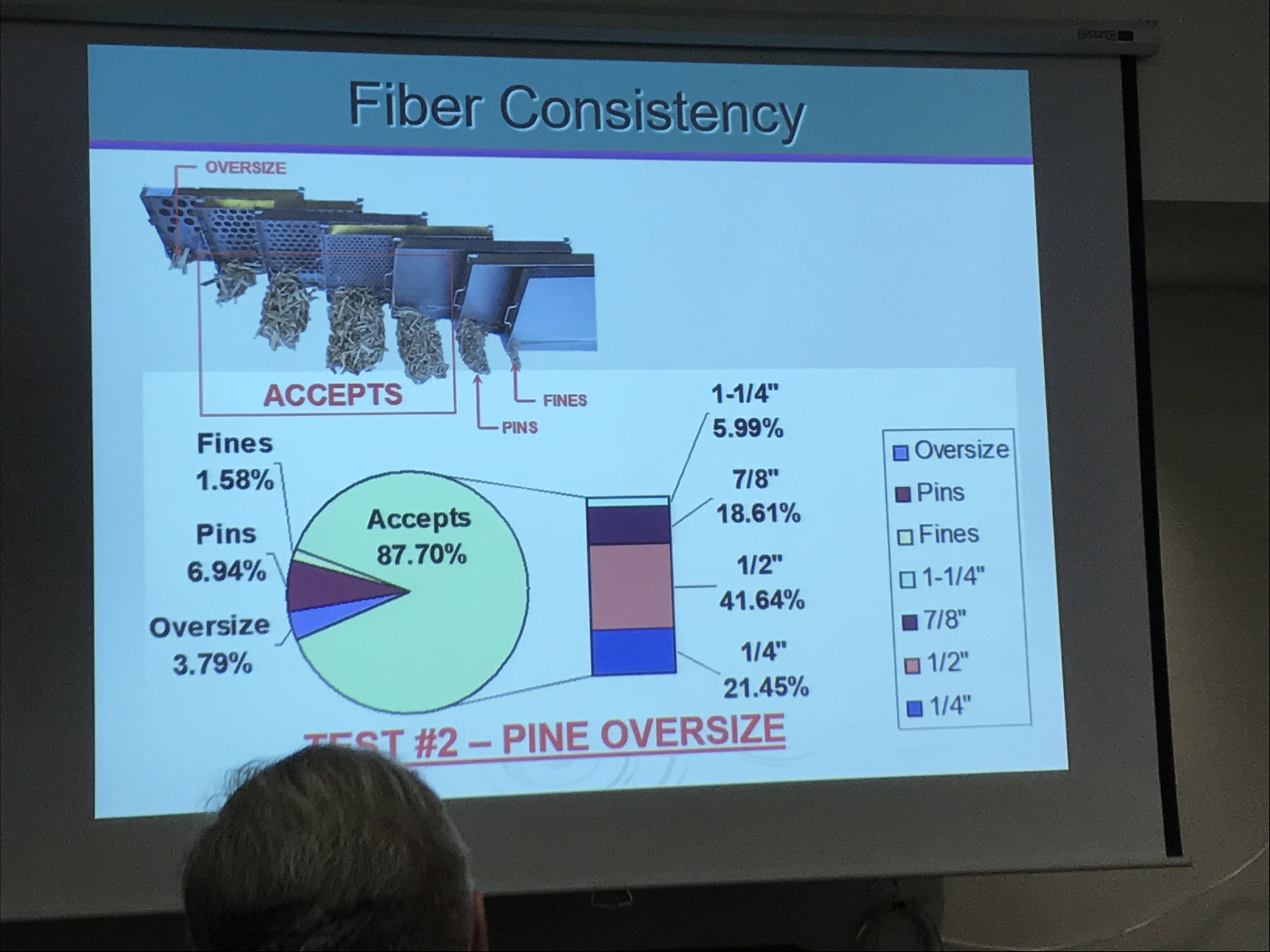

Chris Veley walked us through using a chipper shredder to size the biomass for more efficient processing and maximizing the extraction process. By uniformly sizing the material you can pack more into the processing hopper at a time, up to 40%! Plus, the exposed surface area of the material makes extraction more efficient.

In the video below, Milan talks about transplanting the clones into the field. He will get them sized up to an 8″ pot at most so he can still use mechanical transplant methods and avoid manually planting.

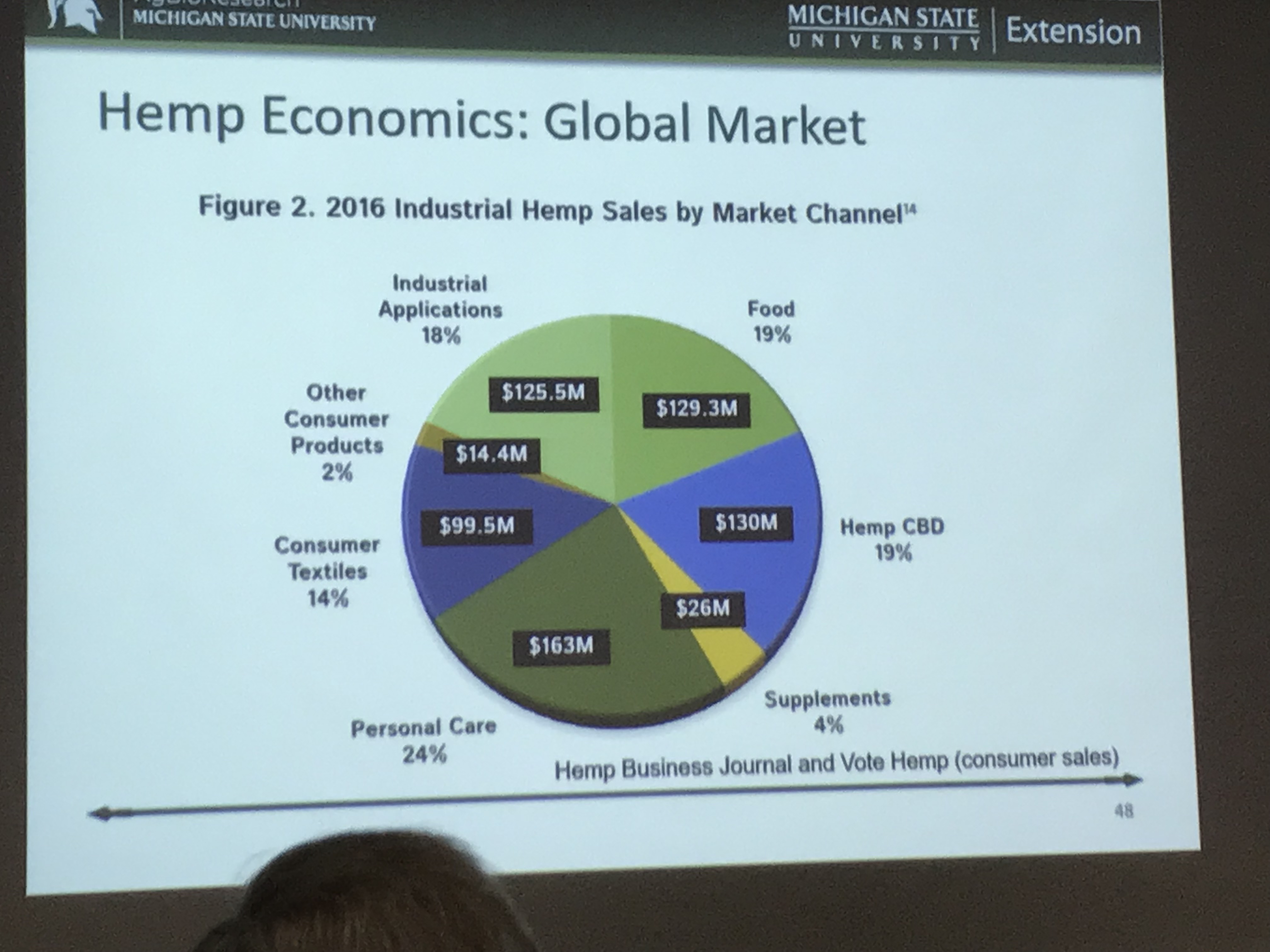

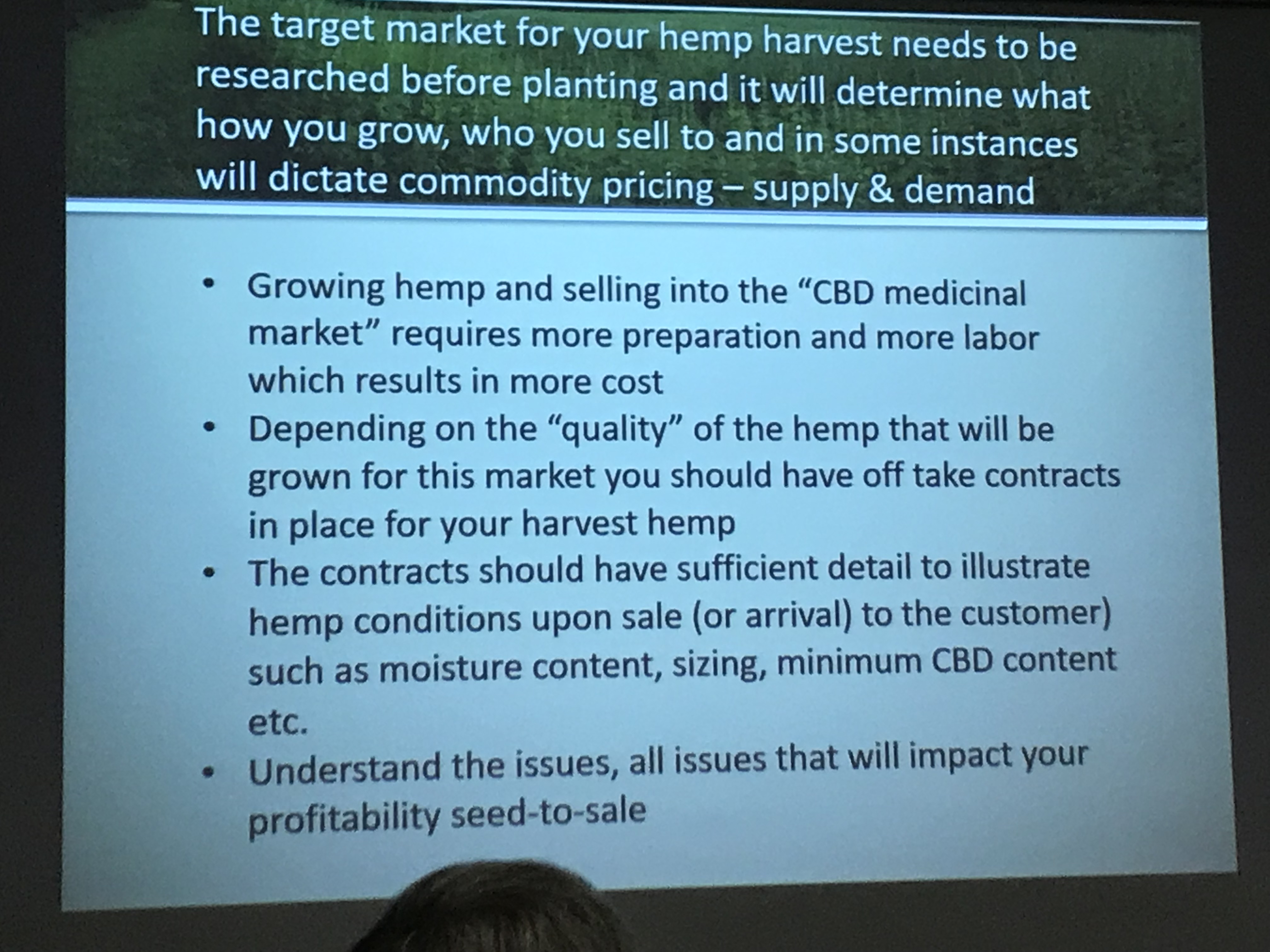

CBD Market

Milan shared much of his experience in growing and processing hemp for CBD oil.

Growing for CBD medicinal market is more labor intensive but the profits are greater. Your customer is going to dictate specifications for your hemp. He targets over 10% CBD hemp with 10% moisture content to process.

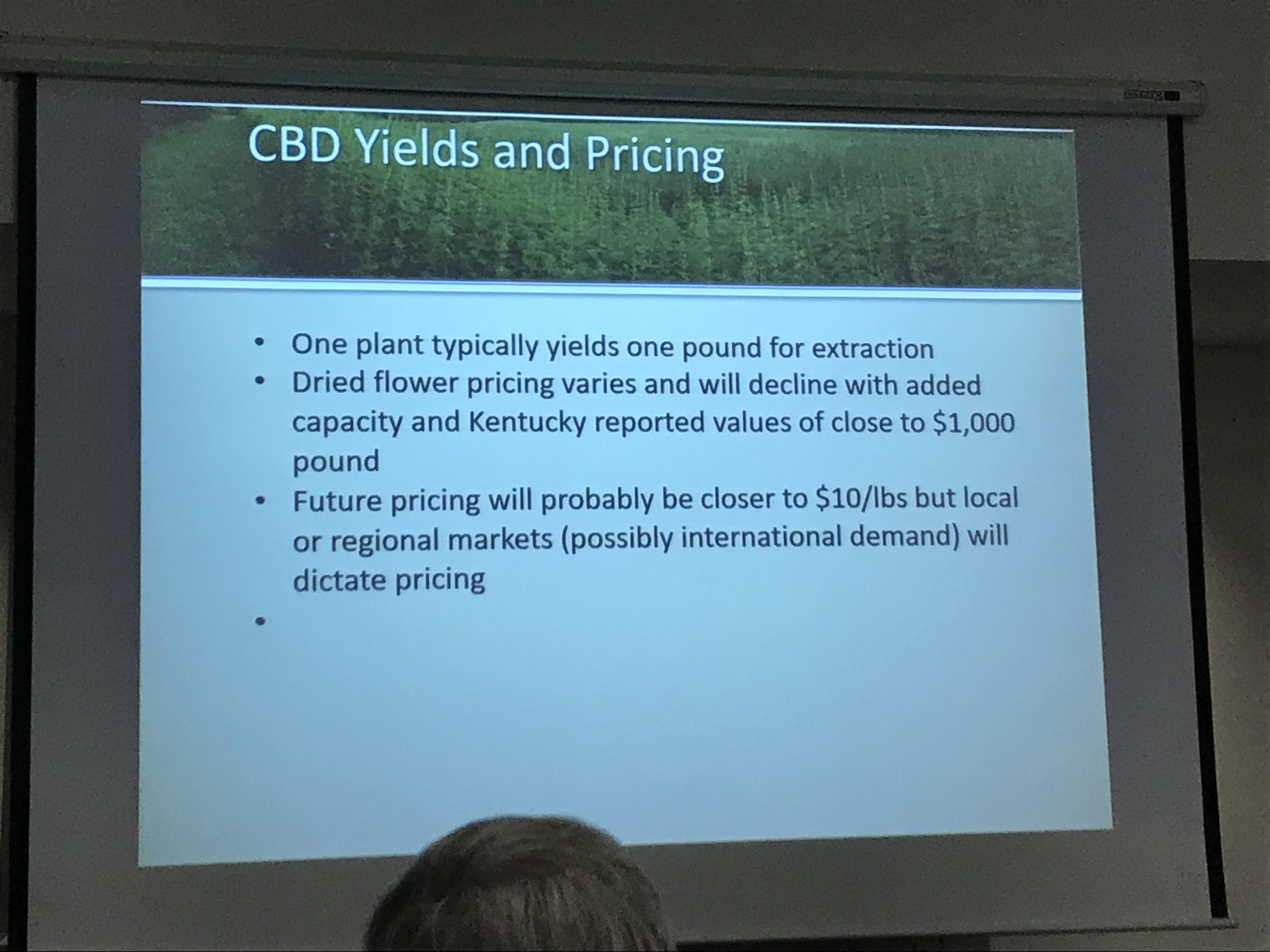

We are still learning about the market and the pricing. On these slides is a price per pound of up to $1,000, which is way above any numbers that have been floated by any processors I’ve spoken to. We are hearing market prices of $25 to $35 per pound. Milan predicts that is will drop down to the $10 level when the market matures.

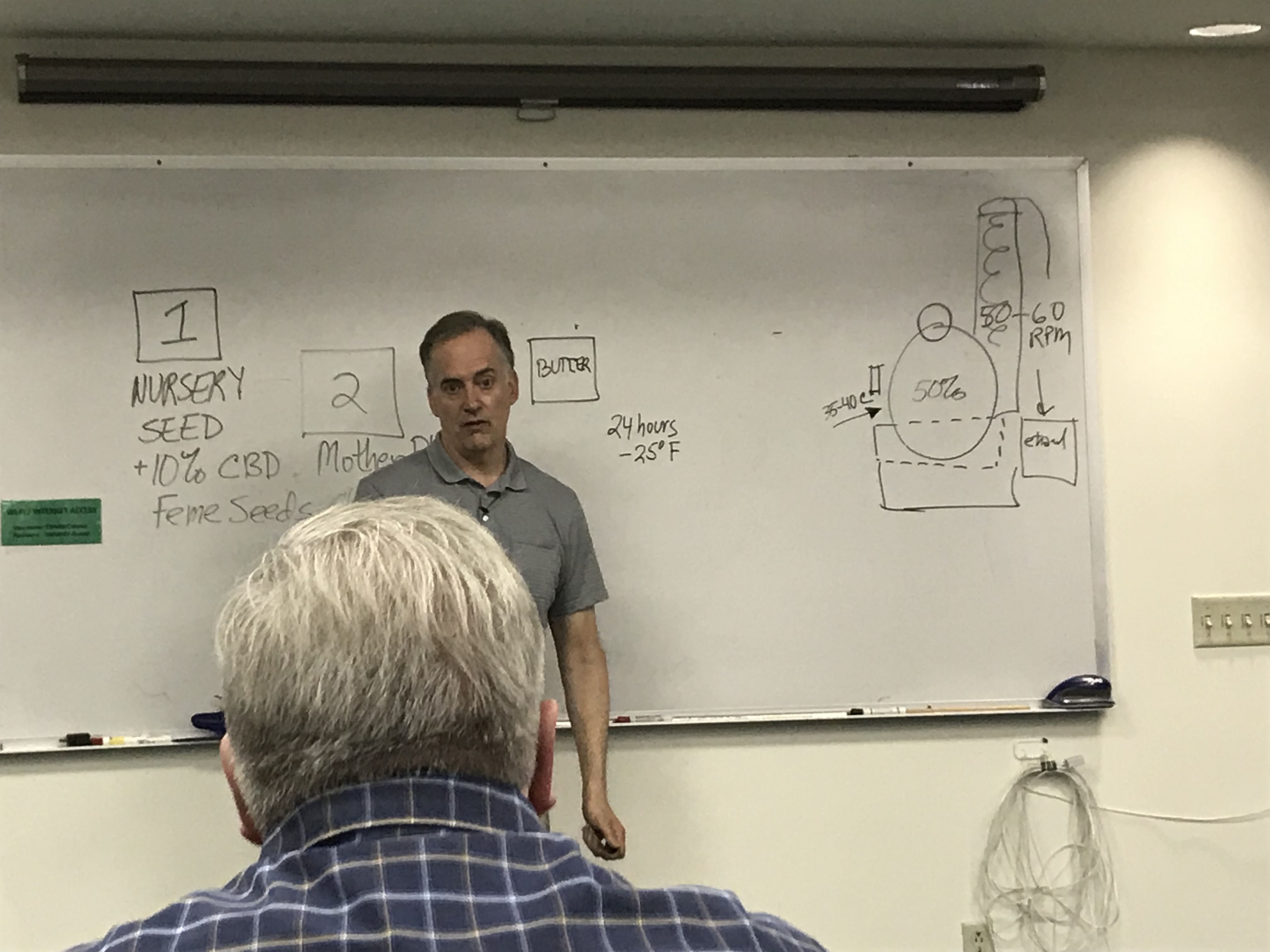

To grow high-value CBD flower, Milan suggests starting with a feminized seed that has a Certificate of Analysis of over 10% CBD. Grow a few “mother” plants and clone them and the clones to produce thousands of clone plants. This process with growing the mother and starting the clones should begin in February to allow time to produce your plants for a May planting. Milan uses coco peat to grow the plants in and monitors the water PH with sensors in a verticle planting arrangement. He has done extensive trial and research on lighting and uses a dimer and timer system to mimic natural light conditions for the plants.

Once planted outside allow to grow for 100 to 110 days. He prefers tall varieties instead of bushy plants due to the potential mold issues.

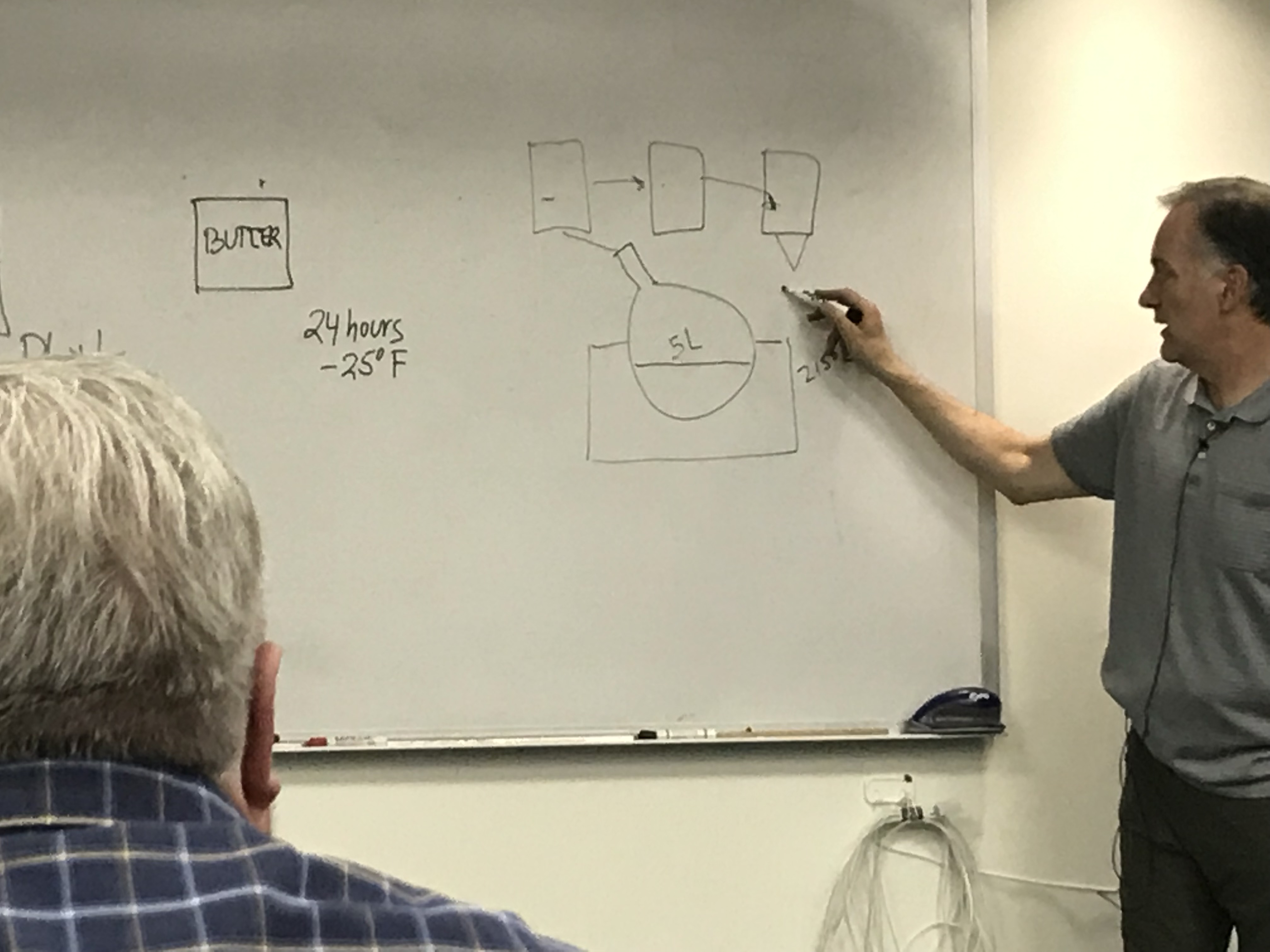

Processing can be completed using CO2 or Ethanol systems. The ethanol offers higher capacity equipment. He looks for lab grade equipment and is very mindful of the cleanliness of his processing lab. The type of processing and degree to which it is processed will depend on your client.

For most farmers, I can see that they will find a processor to work with. This is a deep topic that won’t be fully dealt with in this post.

A Special Thanks to Our Sponsors